Drones taught 3D printing in the air : here’s what it looks like

(ORDO NEWS) — Scientists from the UK and Switzerland have presented Aerial Additive Manufacturing technology, which allows 3D printing of structures in the air using two types of drones.

In the future, not only people will build, but also drones. By the way, the latter have already learned how to print three-dimensional structures in the air.

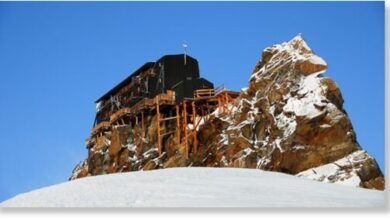

Building or repairing structures in hard-to-reach areas is a difficult task, as getting cranes, scaffolding, and other equipment to certain areas can be very difficult or even impossible.

That’s why scientists are building a system that uses flying drones to do the job. By the way, the researchers came up with this technology after seeing enough of the bees.

Drones for 3D printing

There are two types of machines in the drone 3D printing system. The first one is called BuilDrone. Working from a shared digital blueprint, several of these machines work together to create a three-dimensional structure by extruding layers of material, such as wet concrete, through a nozzle on the underside.

The drone head is able to move sideways relative to the craft to compensate for any accidental drift.

The second type of drone is called ScanDrone. They control the printing process by evaluating the geometry of the design as it is created.

Based on their observations, they advise BuilDrones what to do next in order to stick to the predetermined plan.

At present, the manufacturing accuracy of the system is ±5 millimeters. And although it is designed to work autonomously, the human operator remains in the know, so if necessary, he can intervene and turn on manual control.

In small trials carried out so far, Aerial-AM has been used to create a 72-layer, 2.05-meter high polyurethane foam cylinder and a 28-layer, 18 cm diameter cylinder made from a special cement-like material.

—

Online:

Contact us: [email protected]

Our Standards, Terms of Use: Standard Terms And Conditions.